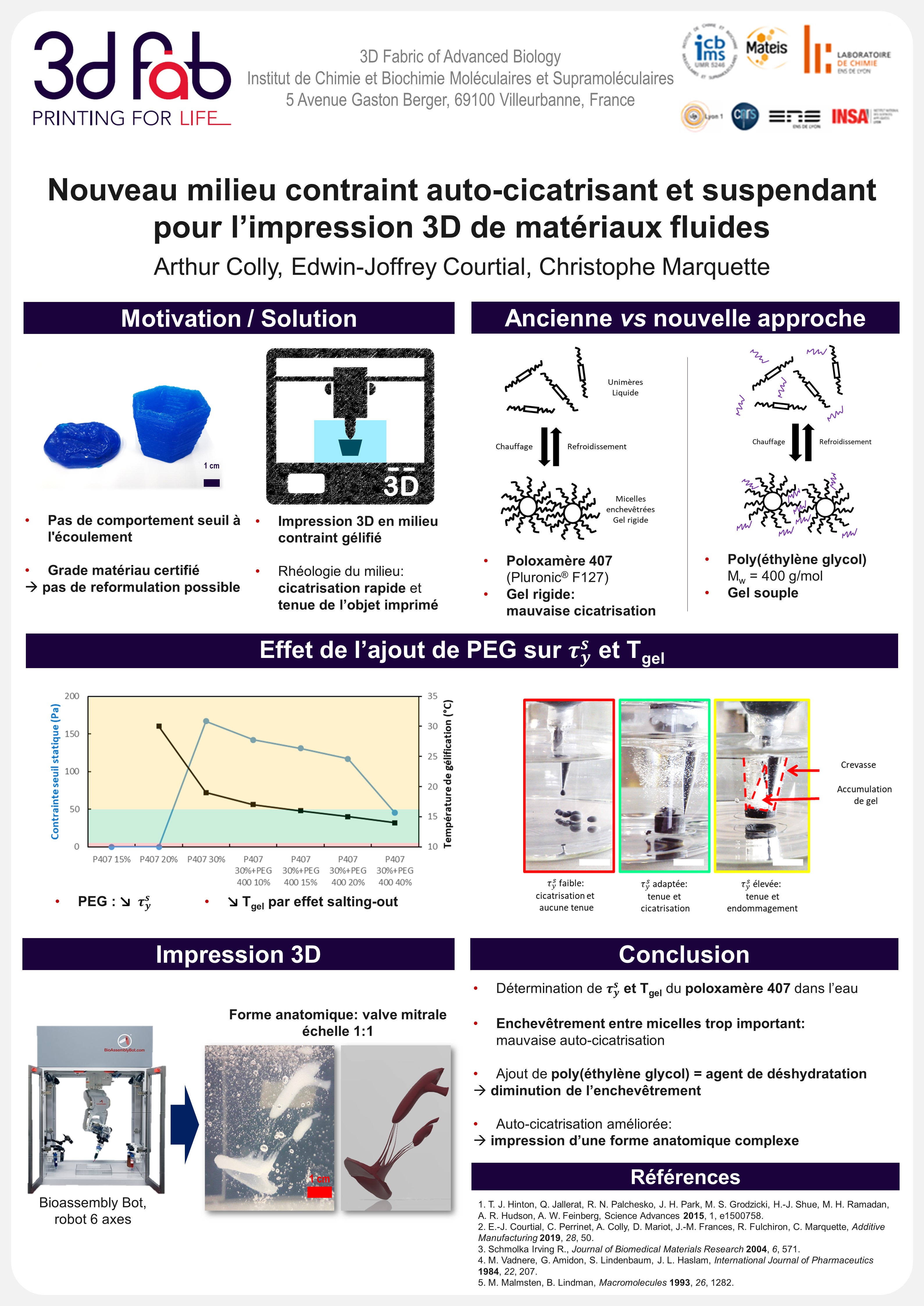

SIn the medical field, 3D printing using material deposition present limitations on printing soft materials from fluids, like silicones. 3D printing in support medium (FRESH) overcome these limits with the holding of the printed material, without collapse, during its liquid-solid transition. The success of this technique relies on the rheological properties of the support medium, which needs to be tailored and understood, thus enabling its self-healing during the process while holding the printed shape.

In this study, we developed a new approach which enables the tailoring of the static yield stress of the poloxamer 407 hydrogel used as a support medium for 3D printing thanks to the addition of poly(ethylene glycol) (PEG). In order to understand and determine the strengths of this self-healing support medium, rheological measurements and 3D printing were performed. Poloxamer hydrogels forms by micelles entanglement. Here, adding the PEG disturbs this entanglement by dehydration of the hydrophilic parts of the polymer due to the salting-out effect. This enables a precise control of the static yield stress of the hydrogel and an easier printing of fluid materials by material deposition.

To demonstrate the strength of this technique, an anatomical shape, a mitral valve, was 3D printed from a fluid material. Furthermore, the understanding of structure-properties relations of the poloxamer 407 hydrogels allow us to extend this technique in the bioprinting field to answer the challenges of regenerative and personalized medicine.

Comments are closed