We have at your disposal several 3D printers, with different technologies :

- Brand new high quality/GLP compatible bioprinter:

see this page.

The 3D printer, injects and hardens instantly tiny UV photopolymer liquid droplets. Thin layers accumulate on the build tray to create an accurate 3D model or part. When raised or complex parts require support, the 3D printer injects removable media gel-like material.

The 3D printer, injects and hardens instantly tiny UV photopolymer liquid droplets. Thin layers accumulate on the build tray to create an accurate 3D model or part. When raised or complex parts require support, the 3D printer injects removable media gel-like material.

Resolution max : from 28 µm in the Z axis.

Maximum volume : 300x200x150 mm.

- Photopolymerization with DLS (Digital Light Processing) by B9 Creator :

Stereolithography is an additive manufacturing process which employs a VAT of liquid curable photopolymer and a video projector to build parts’ layers one at a time. For each layer, the beam traces a cross-section of the part pattern on the surface of the liquid resin. Exposure to the light solidifies the pattern traced on the resin and joins it to the layer below.

Resolution max : 30 µm on the XY axis and 5 µm on the Z axis.

Maximum volume : 104x76x200 mm

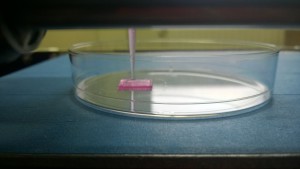

- FDM (Fused Deposition Modeling) by Tobeca :

In fused deposition modeling, the model is produced by extruding filament of material which harden immediately to form layers. A thermoplastic filament that is wound on a coil is unreeled to supply material to an extrusion nozzle head. The nozzle head heats the material and enables a construct layer-by-layer. Typically stepper motors are employed to move the extrusion head and adjust the flow. The head can be moved in both horizontal and vertical directions, and control of the mechanism is typically done by a computer-aided manufacturing (CAM) software, here Repetier Host.

In fused deposition modeling, the model is produced by extruding filament of material which harden immediately to form layers. A thermoplastic filament that is wound on a coil is unreeled to supply material to an extrusion nozzle head. The nozzle head heats the material and enables a construct layer-by-layer. Typically stepper motors are employed to move the extrusion head and adjust the flow. The head can be moved in both horizontal and vertical directions, and control of the mechanism is typically done by a computer-aided manufacturing (CAM) software, here Repetier Host.

Resolution max : from 40 µm in the XY axis.

Maximum volume : 200x200x250 mm.

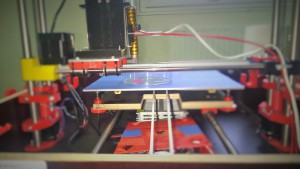

- Bioprinting prototype :

Here we have a in-house developed open source bioprinter prototype.

It uses the same process than plastic extrusion but with syringe-pump, biopolymer and cells instead of plastic filament and thermal extrusion.